ALL TYPES OF MACHINE/MOTORS

Akis

– Full range and properly intercalated within the driving torque range 140 to 900Nm for payload 240 to 1600kg in roping 2:1;

and 320 to 800 kg in roping 1:1

– Energy and space savings’

– Highest level of safety, in accordance with UNI EN81-1:1998+A3:2009 and EN81-20/50 certified by TÜV SÜD

– Smooth and noiseless ride

– High torque reserve

– No oil (no risk of contamination or fire)

– Motors supplied with terminal board without outgoing cables

– Winding thermal protection always present (3xPTC)

– Possible power supply with single-phase and three-phase drive

– Motor protection class: IP44 – TENV execution

– IP64 absolute and incremental encoders (Endat-sincos-HTL-TTL) in IP64, always inside the motor overall dimensions and with a protection cover against damages

– Encoders supplied with 5 m-long outgoing cable without connector

– Brakes according to UNI EN81-20/50 and certified as part of the protection system against uncontrolled upward movements of the cab

– Brakes certified for EN81-1:1998+A3:2009

Modern gearbox on bearings with oil for life thanks to a special high viscosiy synthetic oil.

Suitable for installation up to 1600 kg roping 1:1 and 3000 kg roping 2:1and cabin speed up to 1.6 m/s.

Compact dimensions featuring a significant static load (6000 kg) without outboard bearing (isostatic shaft)

On request it can be equipped with safety brake of ultimate technology made by Alberto Sassi (Patent pending).

Alberto Sassi-MF84

Alberto Sassi-Toro

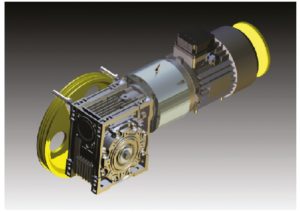

Toro follows the concept of the gear of ‘new generation’ started with Leo and Geko. This new gear replaces the traditional machine MFMB58 offering the same features of the previous Sassi gear. Toro is very compact and versatile with a static load up to 4200kg. Has three positions (vertical, horizontal right and left) and the motor can be turned in order to fulfill all installation requirements. The motors are VVVF and 416 poles. Drum brake and permanent lubrication. Toro has spoked pulleys and sheaves from Ø320 to 700mm.

Very compact and functional machine specially designed for the 3, 4, 6 passengers lift and speed up to 1 m/s, with integral body and rotor directly mounted on worm shaft, without connection fittings (A4) and hand wheel placed opposite to the motor. The machine is provided in a version that can be easily disassembled, removing stator, brake and traction sheave for easy transportation and installation into existing machine rooms, often located in not easily accessible places.

GEM HW134

The ITG 090 can be installed in vertical and horizontal position, thus allowing to satisfy any need of installation. Thanks to its 590 kilograms of static load (for the version with traction sheave) the ITG 090 is perfectly suitable for installations with heavy car frames and cabins. ITG 090 has been conceived for meeting the highest possible safety standards, exactly those required by the European norm for the passangers and goods elevators. The ropes used for both the versions with traction sheave and drum have the 8 millimetres diameter. The ITG 090 is lubrificated by a synthetic polygole oil that, under normal working conditions, requires no replacements.

ITG 090

ITG 134

The ITG 134 can be installed in vertical and horizontal position, thus allowing to satisfy any need of installation and allows you to change from right to left hand and viceversa in minutes, simply by releasing four bolts and turn the motor and the complete brake system. This gear has the higher static load of its segment (3400 kilograms) and his lubrification is granted by a poliglygole synthetic oil that under normal working conditions requires replacement only after 20,000 hours. ITG 134 has been designed in order to be really user friendly for its maintenance.

New gear extremely compact suitable for the new installations and specially designed for the modernizations of old installations, low weight, integrated brake drum, can be mounted in vertical and horizontal.

Compact gear suitable for the new installations and modernizations of old installations. Given Its low weight and dimensions the difference between vertical and horizontal position is almost annulled. The design is new thanks to the presence of integrated brake drum. There is only one brake type: with drum. This gear can be mounted in vertical and horizontal right/left position and both brake and terminal box can be turned 180° to facilitate the installation. Speed motor at 4/16 poles. The project of the VF motor is completely new: with one motor type and with the same reduction ratio you can cover the most common installation’s requirements; these motors (VF-SD motor) are designed to run both with star and delta connections always at 400V, thus allowing to choose the required power with the same motor. The maintenance operations are less frequent and easier thanks to the permanent lubrication of wormwheel and bearings and to the easy operations of motor fitting/unfitting. Extremely noiseless: Geko can be equipped with many accessories among which the brake on the slow shaft and the electric/manual manouvre.

VF Motor

VF Motors

Compact and versatile small dimension gear, vertical or horizontal configuration, drum or disc brake, 4/16 poles and VF motors.

Compact and versatile gear able to adapt the already small dimensions to the most varied installation requirements.

Vertical or horizontal configuration with right or left-hand sheave.

Inclined worm shaft axis.

Speed motor at 4/16 poles and VF.

The motor and the brake can revolve around the worm axis.

Encoder coupling with drum brake is now available.

Double brake type:

– drum brake for all motors

– double front discs only for VF motors

Lubricated for life.

The cost-effective solution to refurbish the old installation lifts, integrated brake drum, can be mounted in vertical and horizontal.

With one motor (VF star delta) and one reduction ratio (1/37), Mody allows you to modernize, according to safety rules, most existing lifts.

Now Mody is available in three installation positions: vertical, horizontal left and horizontal right.

lubrificated for life.

VF Star Delta

GEM MOTOR

Gem General Elevator Machines are very compact and functional machine specially designed for the 3, 4 – 6 passengers lift and speed up to 1 m/s, with integral body and rotor directly mounted on worm shaft, without connection fittings (A4) and hand wheel placed opposite to the motor. Worm shaft and worm wheel are running on high precision bronze bushings and on utmost quality ball bearings for the axial constrain, worm wheel is made by special alloy (centrifuged bronze with nickel) and traction sheave is made by spheroid cast iron.

The machine is provided in a version that can be easily disassembled, removing stator, brake and traction sheave for easy transportation and installation into existing machine rooms, often located in not easily accessible places.